APANI AP1 500 PRO

Amortized in 6-9 months

Chemical-free

Cleans screws, edges and 3D curves

The base material remains intact

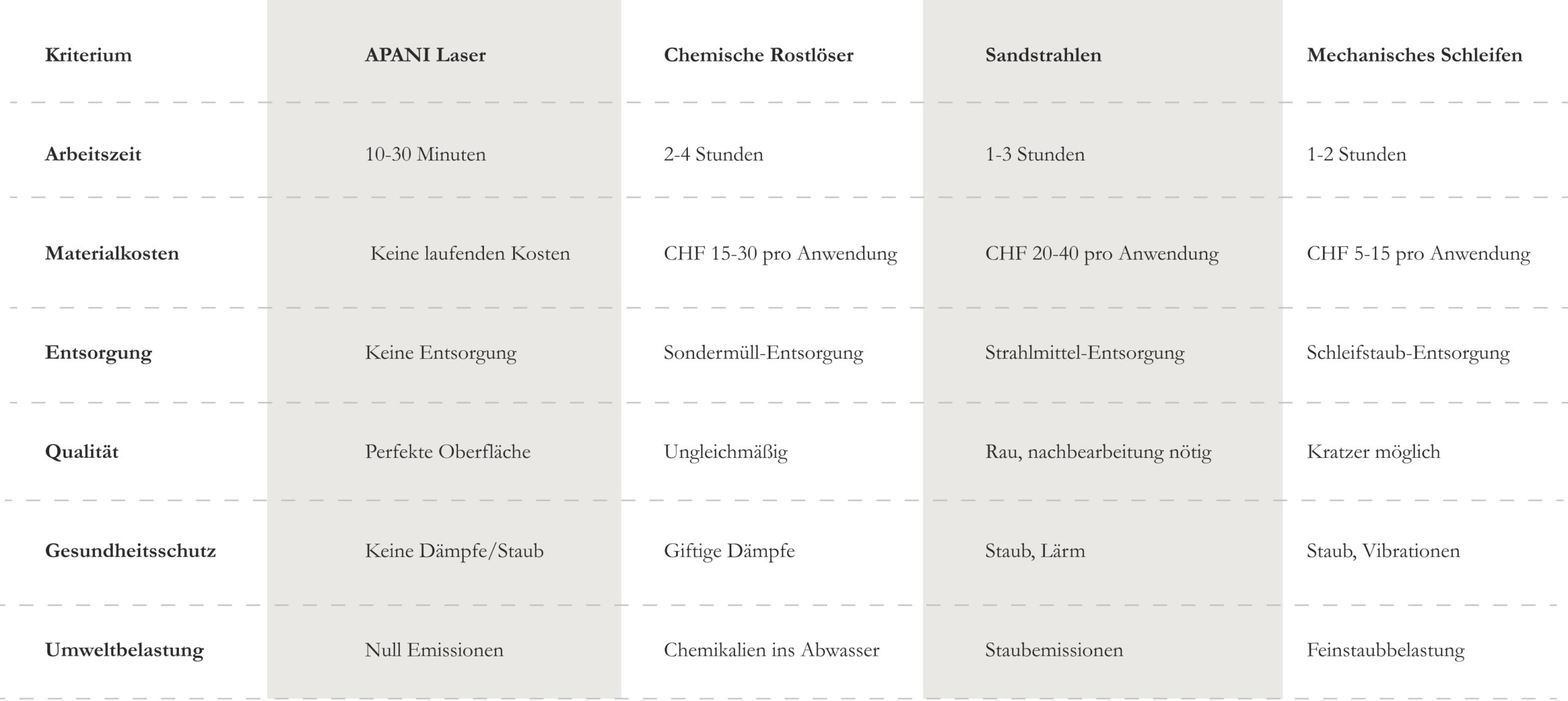

Rust removal

Our cleaning laser in direct comparison

Until now

- 3 to 4 hours of work

- Chemical process

- Masking necessary

- Inaccurate, especially with shapes

- Disposal costs

Ap1 500 Laser

- 15 to 30 minutes of work

- Laser beam only

- no taping

- Precision in all forms

- No disposal

Graffiti removal

Graffiti vandalism costs you time and your customers money. Chemical cleaners harm the environment and often damage surfaces. With the Apani laser, you can remove paint and graffiti completely from stone, concrete, metal, and even glass – without chemicals, without high pressure, without hassle.

Our cleaning laser in direct comparison

Until now

- Aggressive chemicals needed

- Multiple applications required

- The subsurface is being attacked.

- Environmentally harmful

- Protective equipment required

Ap1 300 Laser

- Laser beam only

- A single application is sufficient

- Substance remains intact

- 100% environmentally friendly

- Minimum protective equipment

Paint removal

Old layers of paint must be removed before new paint can adhere perfectly. Sanding is tedious, paint stripping is toxic, and sandblasting is harsh. The Apani laser precisely removes only the paint – layer by layer or all at once – leaving the primer or metal perfectly prepared.

Our cleaning laser in direct comparison

Until now

- Hours of grinding work

- Chemical paint strippers

- Uneven results

- Material loss due to abrasion

- Disposal as hazardous waste

Ap1 300 Laser

- A distance of minutes

- No chemicals

- Consistent results

- Material preservation

- Residue-free evaporation

Oil removal

Oil and grease on concrete, in workshops, or on industrial floors are not only unsightly but also dangerous. Conventional cleaning methods only cover the surface. The Apani laser vaporizes the penetrated oil deep into the pores – for permanently clean and safe surfaces.

Our cleaning laser in direct comparison

Until now

- Oil binders only apply superficially

- Pressure washer smears

- solvents are harmful to the environment

- The risk of slipping remains.

- Regular repetition is necessary.

Ap1 300 Laser

- Deep pore cleansing

- Residue-free evaporation

- No chemicals needed

- Grippy, safe surface

- Long-lasting cleanliness

Weld removal

Our cleaning laser in direct comparison

Until now

- Mechanical brushing/grinding

- Apply and remove pickling pastes

- Irregular surface finish

- Risk of overheating

- Time-consuming manual work

Ap1 300 Laser

- Touchless cleaning

- No chemicals

- Perfectly even finish

- No heat input

- Automatable for mass production

Why Apani Laser?

Specifically developed for the requirements of body shops – from rust removal to paint preparation.

APANI Sapphire Laser for your business?

Fast amortization

Only 6 months until full amortization for small to medium-sized body shops. You save quickly through the elimination of chemicals and reduced working time.

100% environmentally friendly

No chemicals, no water – just lasers. Reduce disposal costs and meet all environmental regulations without extra effort.

Gentle technology

40,000 laser pulses per second with scanning speeds up to 40,000 mm/s. What used to take hours, you can now do in minutes.

Extremely fast

Non-destructive cleaning – removes only what needs to be removed. Rust and old paint disappear, the base material remains intact.

Swiss quality

Patented technology by Prof. Dr. Bodo Lambertz. Works reliably from -30°C to +70°C and up to an altitude of 5000m.

Easy to use

Intuitive remote control on the laser head with distance measurement. Even untrained employees can operate the device after a short training session.

Excellent innovation

AP1 500 Pro

-

Maximum mobility

design with ergonomic weight distribution for fatigue-free work anywhere. -

Patented stability

pyramid technology guarantees vibration-free operation and precise results even on uneven surfaces -

Swiss quality

5-year guarantee, developed and manufactured to the highest quality standards for continuous use -

Ready to use immediately

plug & play with any 230V socket, no installation, no additional devices, no waiting time

Patented Swiss technology

Pyramid design

Patented conical shape ensures improved stability, optimal heat dissipation, and minimal maintenance. Compact footprint saves space in the workshop.

Break-Away Protection

Unique protection of the fiber optic cable thanks to 304 stainless steel wire rope. Prevents costly damage in case of accidental pulling on the laser head.

Sapphire technology

330W sapphire laser with 40,000 pulses per second. High-precision cleaning with constant power and long service life.

AFMD system

Automatic focus and modulation control ensures even energy distribution and constant cleaning quality across the entire surface.

Smart Control

Remote control directly on the laser head with digital distance meter. Over 20 languages available. Simple parameter setting for every application.

Extreme Conditions

Operates reliably from -30°C to +70°C and up to an altitude of 5000m. Dual cooling with automatic temperature adjustment for maximum operating time.

Innovation for your industry

Car bodies

The Apani Sapphire Laser revolutionizes vehicle detailing. Remove rust, old paint layers, and undercoating in minutes instead of hours – without chemicals, without dust, and without damaging the base material. Perfect for classic car restorations, accident repairs, and professional vehicle detailing.

Metal construction & plumbing

Maximum efficiency in metalworking. Cleaning weld seams, removing mill scale, preparing surfaces for coatings – all with one device. The Apani laser saves up to 80% time compared to conventional methods and operates without consumables.

Historic preservation

Gentle cleaning of historic building fabric without mechanical abrasion. Remove paint, graffiti, dirt, and corrosion from sensitive surfaces such as natural stone, wood, or historic metalwork. The non-contact laser technology preserves the original material and meets the highest standards of historic preservation.

Construction industry & facade technology

Efficient surface preparation for renovations and refurbishments. Remove old coatings, adhesive residue, and dirt from concrete, stone, and metal. No scaffold vibrations, no water damage, no abrasive waste disposal.

Shipbuilding & Marine

Top-level corrosion protection and surface treatment. Remove rust, antifouling, and old coatings without sandblasting. No water contamination, no blasting media disposal. Ideal for shipyards, boat builders, and port facilities.

Aerospace

Precision cleaning for critical components. Remove coatings and contaminants without affecting the material structure. Perfect for turbine blades, landing gear components, and surface preparation before NDT testing.

Art & Cultural Heritage

Gentle restoration of valuable objects. From sculptures and picture frames to archaeological finds – the laser removes dirt and corrosion without mechanical contact. Its precise controllability allows for the selective cleaning of even the finest details.

Mold cleaning & injection molding

Extend the lifespan of your tools. Clean injection molds, vulcanizing molds, and die-casting molds without disassembly or chemicals. Reduce downtime by up to 90% and improve product quality through residue-free cleaning.

Oil, Gas & Energy

Maintenance without compromising safety. Remove rust and coatings in potentially explosive atmospheres – the laser is ATEX-certified and operates without sparks. Ideal for pipelines, tanks, refineries, and power plants.